Bespoke Definition According To Wikipedia:

Bespoke shoes are shoes made especially for a certain customer by a shoemaker. The feet are measured and a cast for each foot is created. At the fitting, the customer tries a prototype pair of shoes made in an inexpensive leather and the shoemaker checks if anything needs to be changed. If so, the changes are applied to the lasts and the shoes are created with a precious leather. After the final lasts are created, the customer can order more pairs of shoes without more measurements and fittings.

As defined above, if a personal last for each foot and a prototype pair are not created before the final shoe is produced it is not Bespoke Footwear.

MAIDA'S BESPOKE FINAL PROCESS

FINAL MILLING PROCESS

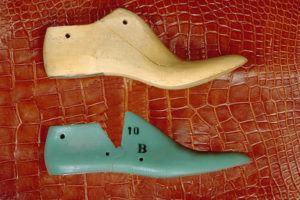

Did you know that there are less than 50 true bespoke shoemakers on the planet. Bespoke shoe making is actually how the art of shoe making began in the 1600’s. Industrial Mass Production of today, is a result of bespoke shoe making, not the other way around. In the world of shoe making the first tool used is a foot shaped mold called a “last”. Whether used in Bespoke or Mass Production shoe making each last model determines the toe shape, heel height and most importantly the fit . There is an old adage used in the footwear industry “the last shall come first” literally meaning that each last model must be developed before design, patterns and production can take place.

There are 3 types of lasts that shoemakers use which we have categorized (below) along with videos. Watch our videos then start reading at the bottom first with Mass-Production Lasts and working your way up to Maida’s Bespoke Last. This will help you understand the way each last type tries to produce a fit. The picture next to Maida’s Bespoke Last pretty much says it all. We feel our last making process is the most advanced and accurate last in the bespoke world. Personal lasts mean less grueling hours of shopping in malls or online in hopes of finding footwear in your size, style and color. It means you to choose from countless styles, colors, exotic leather and patterns and keep using the same last over and over again.

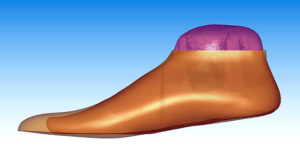

Maida's Bespoke Last

With Maida’s proprietary technology, your lasts are designed and engineered to the exact topography of each foot. This process makes them the most individualized and anatomically correct last available on the market. Maida’s Bespoke Lasts deliver the perfect fit accompanied by all day wear resulting in happy, healthy feet.

Other Processes Cannot Stand On Their Own Two Feet

Traditional Bespoke Last

Method currently used by traditional bespoke shoemakers to produce personal lasts. It involves taking 6-7 girth measurements of each foot using a tape measure, caliper devices and a tracing of the perimeter of the foot. The objective of the last maker is to match the anatomical structure of the customer’s foot using 2D data as a reference to build a 3D model of each foot into a last. If the foot or a 3D model of each foot are not present for reference during the carving of the last, then what data is being used to accurately determine the anatomical structure of the client’s foot? Obviously, there is no 3D data and it is now up to the imagination of the last maker to guess. Additionally, the 2D data is typically not referred to for quite some time (most bespoke makers are 2+ years out) thus escalating the need for more guess work by the last maker. This creates inaccurate anatomical data. This method of last making lends itself to multiple visits for fitting sessions of prototypes before the final pair can be made.

Custom Shop Last

Method of last construction is used globally by custom shops. Technically “made-to-measure”. The shoemaker selects a symmetrical pair of mass-production lasts from an in-house inventory that approximates the client’s measurements. These modified mass production lasts are anatomically incorrect. Existing pairs of lasts are then modified by adding leather or cork (called fittings) to positions aligning with 2D girth measurements and draft (a tracing around the perimeter of the feet). Personal modified lasts typically do not exist in these shops. Lasts are used endlessly by removing fittings and starting over for the next customer. Mass-production lasts are not designed with anatomical features of the human foot to begin with, and with addition of the fittings, the final shape of the last becomes distorted and untrue to the original mass-production last (which was originally designed for fashion purposes). A major concern with modified lasts is that custom shops DO NOT make a prototype for your fit. If you don’t receive a prototype pair, your footwear is made on modified mass production lasts. When you pick up your footwear, it is essentially paid for. If they don’t fit? All custom shops can do is stretch the final shoe and hope it fits. This archaic method leads to many fit and aesthetic errors resulting in unhappy customers.

Mass Production Last

A symmetrical pair of lasts that are straighter in design and do not take into consideration the anatomical shape of the human foot. These lasts are designed for fashion and shelf appeal (fashion and sales before fit), and the straighter shape allows for the ease of manufacturing in mass production. Podiatrists blame the Mass Production Last for many foot related injuries and deformities seen in the wearers toes and ball joint areas. This problem continues because factories in Italy and China (which together produce 90% of the worlds footwear) primarily produce one width for women (“B”) and one width for men (“D”) for the footwear brands found in department stores or online. Only 40% of the population fit B and D widths. If you are in the 60%, then more than likely you are not getting the proper fit.

CONSULTATION

Maida’s requires an initial phone consultation prior to visiting our showroom. If you are ready to begin your custom experience, please give us a call or schedule an appointment.